The Definitive Guide to VAV Selection

Variable Air Volume (VAV) terminal units control the zone temperature, ensure the minimum ventilation air is delivered to the zone, and significantly impact fan energy consumption. A project may have hundreds of VAVs, each with its unique zone load and ventilation profiles. Therefore, properly selecting VAVs is imperative for a cost-effective, code-compliant, and energy-efficient project. Additionally, it is important to remember information from various ASHRAE guidelines and standards, including 62.1, 90.1, and 36. These complications can make selecting VAVs time-consuming and tedious. Approaching VAV selection with a methodical process already set up can allow quicker and optimal VAV selections and enable the selections to be automated; that process is described in this paper.

Forward:

As our industry continues to adopt more advanced Building Information Modeling (BIM) techniques, manufacturers are beginning to produce cloud-based selection software which can be driven by an Application Programming Interface (API). The BIM model can now be directly linked to manufacturers’ selection software, allowing HVAC designers to automatically get size and performance data for HVAC equipment inside Revit.

Combining these technologies is a force multiplier for the HVAC designer’s productivity. Now, not only can an HVAC designer automate heating and cooling load calculations, but those load calculations can be fed directly into a manufacturer’s selection software to automate the selection and layout and diffusers and VAVs. All these automated functions (load calculations, diffuser layout, and VAV selection) are combined in the Ripple HVAC Toolkit, which can be downloaded for free at the Autodesk Revit App Store1 or at www.RippleEngineeringSoftware.com.

The automated load calculations were validated in a paper presented in the July 2022 issue of the ASHRAE Journal. The automated diffuser selection and layout procedure was described in the December 2022 issue of the ASHRAE Journal. This paper describes the engineering procedure for selecting VAVs that the Ripple HVAC Toolkit follows. However, these processes can be followed manually, with or without BIM. And in fact, this is the last time BIM will be mentioned in this article.

Introduction:

The intent of selecting VAVs is so that information can be conveyed to the mechanical contractor, controls contractor, balancer, commissioning agent, electrical engineer, and building operator so that the purchase, installation, balancing, commissioning, and operation of the optimal VAV can be completed in a timely, energy efficient, and cost-effective manner. This information is typically conveyed with mechanical equipment schedules.

ASHRAE Guideline 36, High-Performance Sequences of Operation for HVAC Systems2, was created to develop and maintain best-in-class standardized HVAC control sequences. ASHRAE Guideline 36 reduces energy consumption, cost, and system downtime with more resilient systems, control sequence compliance, and diagnostic software3. It allows engineers to reduce engineering time by adapting standard sequences already proven to perform. It minimizes programming and commissioning time for contractors. The control sequences developed by ASHRAE 36 should be used wherever possible, including for VAVs. To use ASHRAE 36, certain information must be conveyed in the schedules, as described in this document.

ASHRAE Standard 62.1, Ventilation and Acceptable Indoor Air Quality4, dictates many aspects of VAV selection because the minimum airflow in all conditioning configurations must deliver at least enough outdoor air to ventilate the space adequately. 62.1 can also have an impact on the maximum discharge air temperature. The Zone Air Distribution Effectiveness Table 6-4 increases the required outdoor air by 20% if the heating air is supplied and returned from the ceiling because the assumption is that 20% of the air will bypass the space due to the buoyancy of warm air. 62.1 removes this penalty if the warm air is supplied less than 15 °F above the Space temperature (85 °F at a 70 °F space temperature) AND the space air distribution is designed for the air velocity to be 150 fpm within 4.5 ft of the floor which can introduce draft related comfort issues.

ASHRAE Standard 90.1, Energy Standards For Buildings Excluding Low Rise Residential Buildings5, dictates, or at least attempts to dictate, certain aspects of VAV Selection. 90.1 G3.1.3.13 states: “Minimum volume set points for VAV reheat boxes shall be 30% of zone peak airflow, the minimum outdoor airflow rate, or the airflow rate required to comply with applicable codes and standards”. Section 6.5.2.1 limits simultaneous heating and cooling unless the volume reheated is the minimum as dictated 62.1. section 6.5.2.1.1 limits reheat supply air temperature set point to 20 °F above the space temperature set point. In general, when selecting VAVs, most of ASHRAE 90.1 can be ignored by setting VAV minimums to what is required by ASHRAE 62.1. However, it is essential to limit the maximum discharge air temperature to 20 °F above the space temperature setpoint (90 °F at a 70 °F space temperature).

VAV Design Airflow:

ASHRAE 36 recommends leaving VAV minimum airflow calculations for the controls contractor to calculate from the ventilation data provided to them. However, it is essential to understand how the VAV will operate, as described below. A table describing the required calculations and decisions can be viewed as Table 1.

ASHRAE 36 dictates that the designer shall provide six values to the controls contractor:

From these values, ASHRAE 36 expects the controls contractor to calculate the following values:

VCM=4005*√VPminF*Ai

Pressure Drop, Neck Size, Amplification Factor, and VPmin:

A VAV is an obstruction in the air stream; as such, it creates a pressure drop. That pressure drop must be overcome by a fan that uses energy; the more pressure drop, the more fan energy is used. Therefore, selecting VAVs that are too small can create excessive pressure drops and make the system inefficient from an energy standpoint.

On the other hand, notice from our previous calculations that VAV Controllable Minimum (VCM) can drive the VAV minimum airflow, which will drive the available fan turndown. Therefore, selecting VAVs that are too big can create excessive minimum airflow and make the system inefficient from an energy standpoint.

The VCM can be reduced by selecting manufacturers who design the VAV airflow sensor to have a high amplification factor. Amplification factors should range from 1.8 to 4.9, depending on the inlet7.

The VCM can further be reduced by selecting a VAV controller with a small minimum readable velocity pressure, VPmin. Quality controllers can read down to 0.001 in W.C.8.

From a cost and system efficiency standpoint, the smallest VAV capable of delivering the Cooling Maximum Airflow at a reasonable pressure drop, typically 0.5 in. W.C. should be selected.

Noise Criteria:

VAVs create noise because they must modulate air flow by closing a damper. The further the damper must close to modulate flow, the more pressure drop there will be, and the nosier the VAV will be. VAVs create discharge noise, which travels down the duct and may exit air terminals into the space, and radiated noise, which “breaks out” from the VAV and may be heard originating from the VAVs.

VAV noise, both radiated and discharge, can be dissipated by other parts of the mechanical and building systems. Flex ducts on diffuser inlets can reduce discharge noise, while ceilings and insulation between the occupant and the VAV can make for a quiet and enjoyable space.

Noise can further be reduced by providing ample means of balancing to the system. A well-balanced system means the VAV isn’t required to close its damper significantly to compensate for excessive duct main pressure. Downstream dampers to every diffuser are needed to balance the airflow to each diffuser; these can be adjusted back in proportion to keep the pressure drop across the VAV lower. Providing an upstream balancing source can also be beneficial to allow lower VAV inlet pressures. For instance, the top floor served by a rooftop unit may have much higher inlet pressures than the lower floors. Many manufacturers provide the option to use the fire/smoke damper at the shaft exit as a balancing or control device9, which can reduce VAV noise on the upper floors.

Selecting VAVs based on NC is a tough battle because it is difficult to tell what the inlet pressure will be and what the outlet pressure that will be required is. An engineer would have to run pressure loss calculations to every VAV and diffuser to determine the actual inlet and outlet pressure accurately. For this reason, general assumptions can be made about the inlet and outlet pressures. Typically, 1 in. W.C. inlet and 0.25 in. W.C. outlet.

While VAVs create noise by modulating airflow, the required increase of area required to limit the coil face velocity makes them great locations to attenuate noise, both from the VAV itself and from upstream AHU fans. Many different liner options are available that are discussed later in the paper, which helps them accomplish this.

Typically, picking a good liner, limiting VAVs to a reasonable pressure drop, as discussed earlier in this paper, and providing ample means of balancing will make the VAV pressure drop, not the NC, the deciding selection factor in most applications. That said, a maximum discharge and radiated NC, typically 50 for both cases, should be set. In special circumstances, such as recording booths, the engineer should determine what the actual required inlet and outlet VAV pressures will be and reduce the acceptable VAV NC as necessary. In these critical applications, it would also be essential to quantify and handle other sources of noise generation and attenuation.

No Coil Selections:

VAVs can be provided to internal zones with no heating load without a reheat coil. However, VAV minimum flows are based on ventilation load, not thermal load. So VAVs with no reheat coils may dump excessive cold air into a space and overcool a space with a low thermal load. For this reason, it is preferable to provide a small reheat coil to bring the VAV minimums up to a neutral discharge air temperature, even in internal zones with no heating loads.

If the owner decides to sacrifice comfort for upfront costs, VAVs with no coils have a low pressure drop. These can often be selected based simply on the maximum allowable NC.

Heating Water Coil Selections:

VAV heating water coils are not built to order; there are only a handful of standard coil configurations that can be supplied. Therefore, only one performance parameter can be set, and the rest are calculated. Typically, fluid flow rate, discharge air temperature, leaving water temperature, OR capacity can be used.

ASHRAE Standards are most concerned with the VAV’s discharge air temperature (DAT). ASHRAE 90.1 limits the DAT to more than 20 °F above the space temperature setpoint. ASHRAE 62.1 introduces a penalty if the DAT exceeds 15 °F above the space temperature setpoint. For this reason, VAVs should be selected based on DAT. However, this does not mean that the other coil parameters are unimportant. The leaving water temperature is also important for the following reasons:

Because the selections are already being set based on DAT, the exact leaving water temperature will not be able to be specified exactly. However, coil rows can be increased until a maximum LWT (or a minimum waterside delta-T) is met.

For example, even though the heating load may be met with a two-row coil, it may be beneficial to increase to a three- or four-row coil to attain a lower leaving water temperature.

Heating water coils add cost and air pressure drop as rows are increased, this should be allowed up to a point, but the forest shouldn’t be lost through the trees. If the water flow is very low to meet the load, by the time the water mixes with the return water from all of the other VAV and AHU coils, it won’t have a significant impact on the water temperature entering the heating equipment. For this reason, it is practical not to increase coil rows at low water flow rates (GPM).

With these considerations in mind, a hot water coil selection process can be described as follows:

Electric Coil Selections:

Electric coils have a few different considerations than heating water coils. Capacity modulation for coils is typically achieved by staging or a Silicon Controlled Rectifier (SCR). Staging allows the coil capacity to be applied in a certain number of stages. For example, a 6 kW, 3–stage coil can apply 2, 4, or 6 kW depending on the space load. SCRs allow the capacity to be regulated infinitely.

The modulation type affects the coil selection; electric coils require a minimum kW per stage, typically 0.5 kW per stage. Therefore, the desired modulation type should be decided before the coil selection process begins but should be adjusted for the coil selection. For example, a 3-stage heat for comfort modulation may be preferred, but if a small office only needs a 0.5 kW capacity coil, allow the modulation to reduce to 1 stage (on/off).

SCRs provide much more comfortable spaces, more realistic code compliance, and lower required minimums. They should be the control method of choice for the discerning HVAC designer.

Additionally, electric coils require a minimum airflow to keep the coil temperature regulated. This value is typically around 70 CFM/kW applied. Note that this is not based on the coil capacity kW but the kW applied. A 2 kW two-stage heater requires a minimum airflow to satisfy 1 kW (2 kW / 2 stage), typically 70 CFM. An electric reheat coil controlled by a Silicon Controlled Rectifier (SCR) can modulate infinitely and therefore does not have a minimum required airflow.

Electrical coil selections must be coordinated with the electrical engineer. The electrical engineer determines what voltage system (i.e., 480/277) the building will use and what voltage/phase each coil should be. For example, at low kWs, using a 277/1 electric coil can save breaker spaces in panels and feeder counts out to the coil. However, at higher kWs, the decrease in feeder sizes by switching to 480/3 is of more concern. It is also ideal to have a single-phase option because coils require at least 0.5 kW per phase of power. If a small office only needs 0.5 kW of coil capacity, and a 3-phase coil is selected, a 1.5 kW coil would have to be provided.

Electric Coil Selection Process:

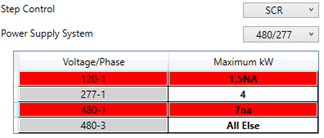

Figure 1: Example control, power system, and breakpoint table.

Other VAV Options/Considerations:

Liner:

VAV liners provide insulation and sound attenuation to the VAV duct system. Generally, manufacturers offer various thickness options; the thicker the material, the better the insulation and sound attenuation. Many manufacturers provide excellent descriptions and pros and cons for each liner type10 , but we will review the different material options for liner:

Hot Water Coil Oversized Casings:

Hot Water Coil Oversized Casings allow a smaller neck size and airflow sensor with a larger coil area. This lowers the VAV Controllable Minimum while still providing the heating capacity and waterside delta-T within a lower pressure drop. This is an excellent option for tuning the equipment to fit the system.

Even Sizes Only:

Manufacturers’ selection software allows limiting selections to even sizes and disregarding 5”, 7”, and 9” round inlets. This has some benefits; sometimes, local vendors only stock even sizes. Sheet metal firms may also provide even-size ductwork at the same cost as a smaller odd size. However, a simple reducer upstream of the VAV solves this problem. For the same reason oversized casings are great (allow the smallest controllable minimum while still providing capacity), odd sizes should be allowed on a project.

High Capacity Coils:

Manufacturers provide the option of standard or high-capacity coils on 1-row and 2-row coils. Typically, standard capacity means 10 fins per inch, while high capacity is 12 fins per inch. Again, a smaller neck size with more FPI allows lower controllable minimums while still providing the capacity; this option should also be allowed.

Demand Control Ventilation (DCV):

DCV optimizes air flow to space based on the actual occupancy as determined by the level of CO2 in the space. The IECC typically requires demand control ventilation in spaces with an occupant density higher than 25 people/1000 sf and an area greater than 500 sf. Demand control ventilation allows the VAV to reduce to minimums lower to below Voz, all the way down to the controllable minimum of the VAV.

The CO2 setpoint should be based on the actual anticipated CO2 concentration in the space, which is a function of the population, Pz, metabolic rate, m, ambient CO2 concentration, Coa, and the ventilation characteristics of the space using the following equation:

CO2anticipated=Coa+8400*Ez*mRp+Ra*Az/Pz

The actual setpoint should be slightly lower than the anticipated CO2 setpoint. If the ambient CO2 concentration is measured, the setpoint can be dynamically calculated using only the right side of the equation.

DCV also decouples the VAV flow from the thermal load, which may cause occupant comfort issues. Consider an exterior conference space fully occupied on a frigid winter day. The skin heating load on the building might fully counteract the interior cooling load and no conditioning is needed. However, the control sequence may drive the VAV to cooling maximum to meet the CO2 load. If the reheat coil was not sized for this, the space may become overcooled. For this reason, it may be appropriate to size the VAV coils to bring the cooling maximum up to neutral discharge air temperature in spaces with DCV.

Sensor Types:

VAVs are typically controlled by a sensor or group of sensors that must be scheduled with the VAV. The sensors may also allow the user to modify the space temperature setpoint and allow the user to view the current environmental conditions. Typically, the sensors are described in the specifications or notes, and only indicators are used on the schedule. Example Indicators include:

Temperature Sensing/Adjustment/Display:

S – Sensor Only – typically provided in public areas where occupants should not be able to override the temperature setpoint.

A – Adjustable Sensor – typically provided in private areas, such as offices, where the occupants should be able to adjust the setpoint up or down.

V – Visual Readout Adjustable Sensor – typically provided in private areas, such as offices, where the occupants should be able to adjust the setpoint up and down and read the current conditions.

CO2 – DCV- for use with demand control ventilation.

O – Occupancy – used for detecting space occupancy and is required for occupied standby mode when integrating with the lighting controller is not available.

A sensor for a conference space might read, “V, CO2, O” Indicating that a visual, adjustable temperature sensor, along with a CO2 sensor and an occupancy sensor is to be provided to control the VAV. Many times, all of these sensors can be provided in one11, but the important thing is that the design conveys to the contractors what must be provided.

Setpoints can be listed on the schedule or grouped and listed in the specification.

Conclusion:

As described in this paper, VAV selection is a complicated and time-consuming process. Thankfully, this process was combined with Price Industries’ cloud-based selection software and automated for BIM projects. Check out the free plugin at www.RippleEngineeringSoftware.com.

Table 1: VAV Airflow Schedule

|

Airflow Information |

||||||||||||||||

|

VAV Minimum |

ASHRAE 36 Inputs |

DESIGN FLOW CONDITIONS |

||||||||||||||

|

Minimum Velocity Pressure (IN. W.C.) |

VAV Controllable Minimum: VCM (CFM) |

Breathing Zone Outdoor Air Area Component, Vbz-A: (CFM) |

Breathing Zone Outdoor Air Population Component, Vbz-P (CFM) |

The Zone Air Distribution Effectiveness in Heating Mode, Eh (Unitless) |

The Zone Air Distribution Effectiveness in Cooling Mode, Ec (Unitless) |

Zone outdoor Airflow in Cooling Mode, VozC (CFM) |

Zone outdoor Airflow in Heating Mode, VozH (CFM) |

Occupied Stand-By Flow (CFM) |

COOLING |

HEATING |

||||||

|

Economizer Minimum Flow |

Minimum Flow |

Maximum Flow |

Economizer Minimum Flow |

Minimum Flow |

Flow Required To Meet Heating Load at Max dT |

MAX / REHEAT FLOW |

||||||||||

|

|

||||||||||||||||

|

VPmin |

VCM = 4005*√(VPmin/F)*Ai |

Vbz-A |

Vbz-P |

Eh |

Ec |

VozC = (Vbz-A + Vbz-P) / EC |

VozH = (Vbz-A + Vbz-P) / EH |

0 If allowed by 62.1 |

Max(VozC, VCM) |

Max(1.5 * VozC, VCM) |

Sum of Space Airflows (Qcool / 1.08 (EAT – ZNTcool)) |

Max(VozH, VCM) |

Max(1.5 * VozH, VCM) |

CFMheatLoad = Qheat / 1.08 * (Max DA-T – ZNTheat) |

CFMHeat = Max(1.5 * VozH, VCM, CFMheatLoad) |

|

References: